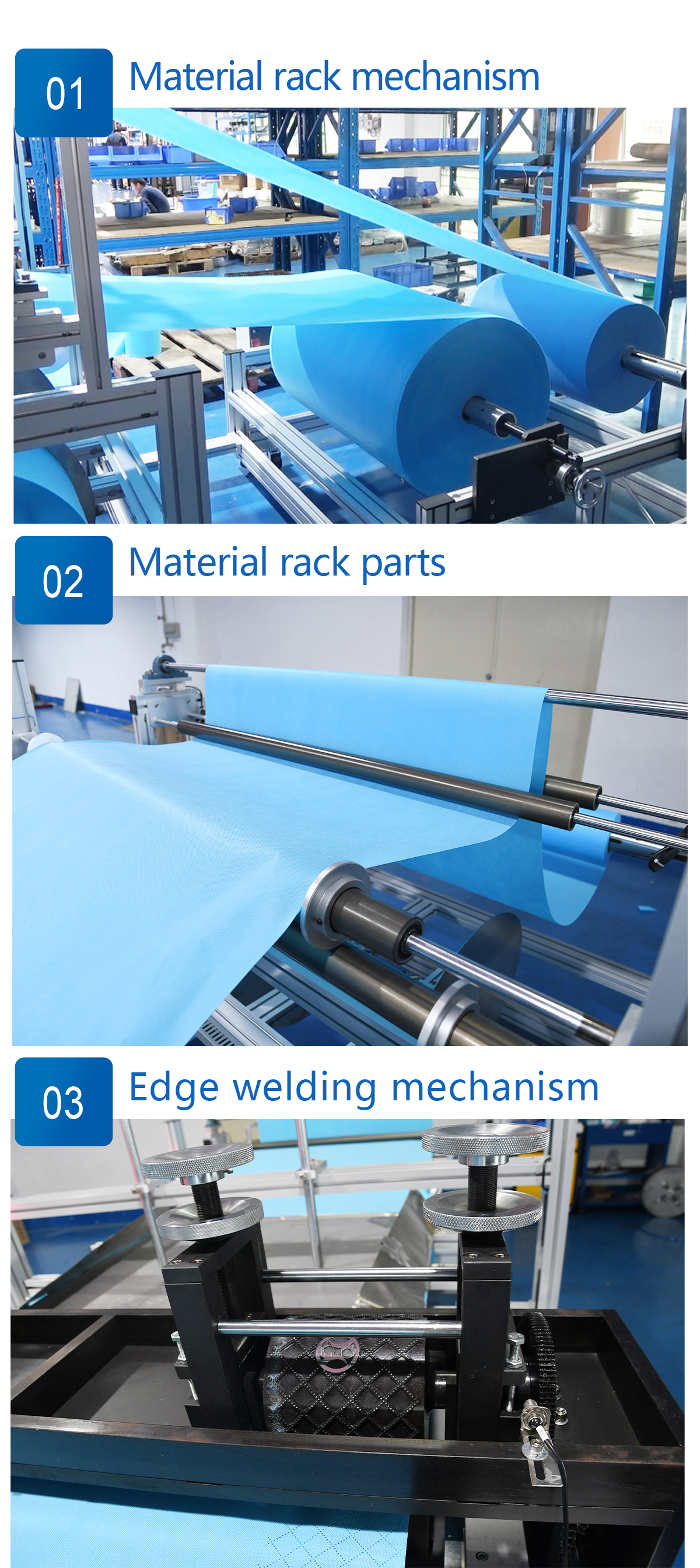

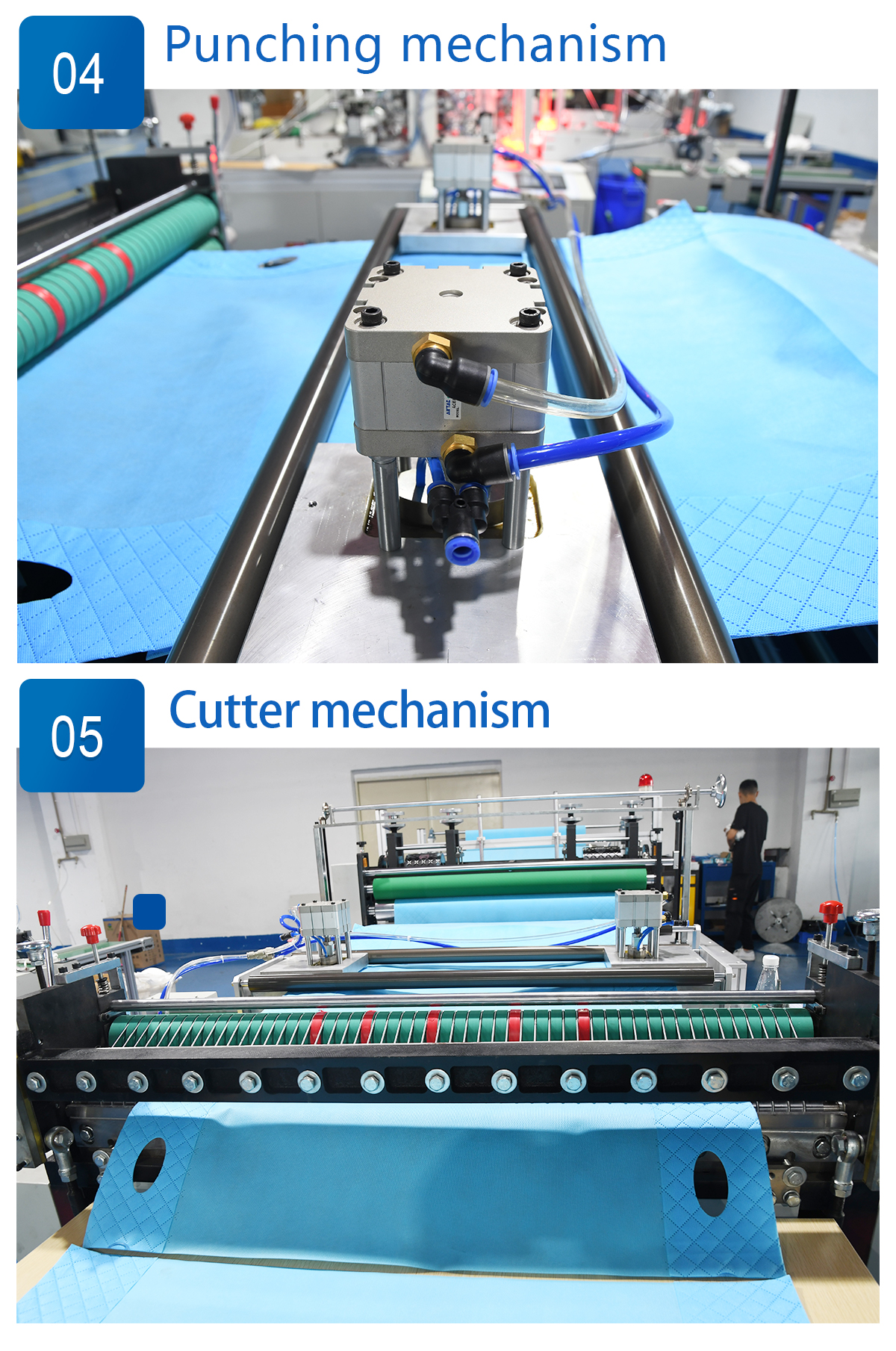

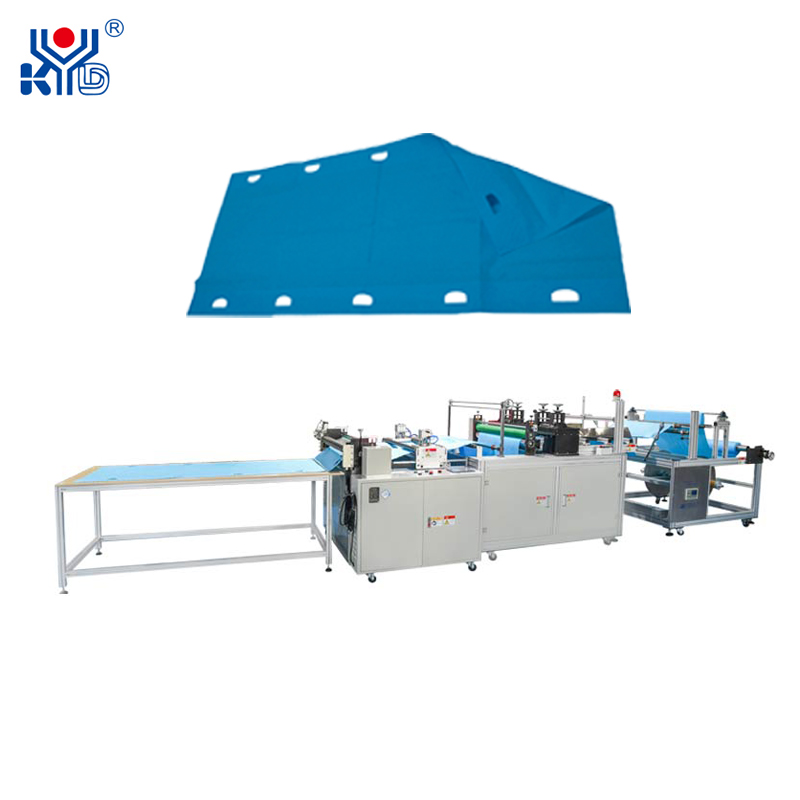

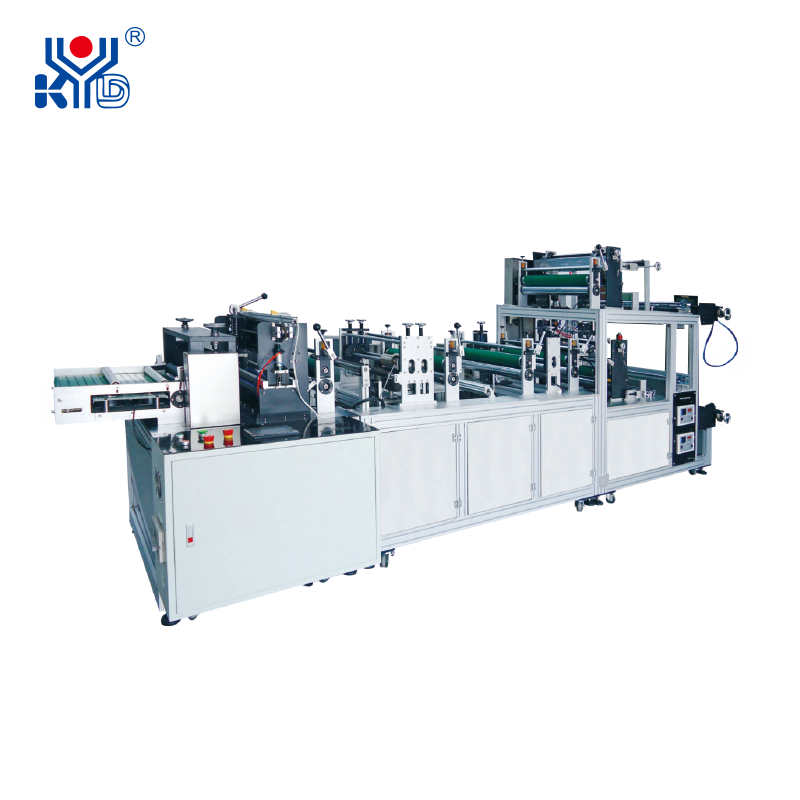

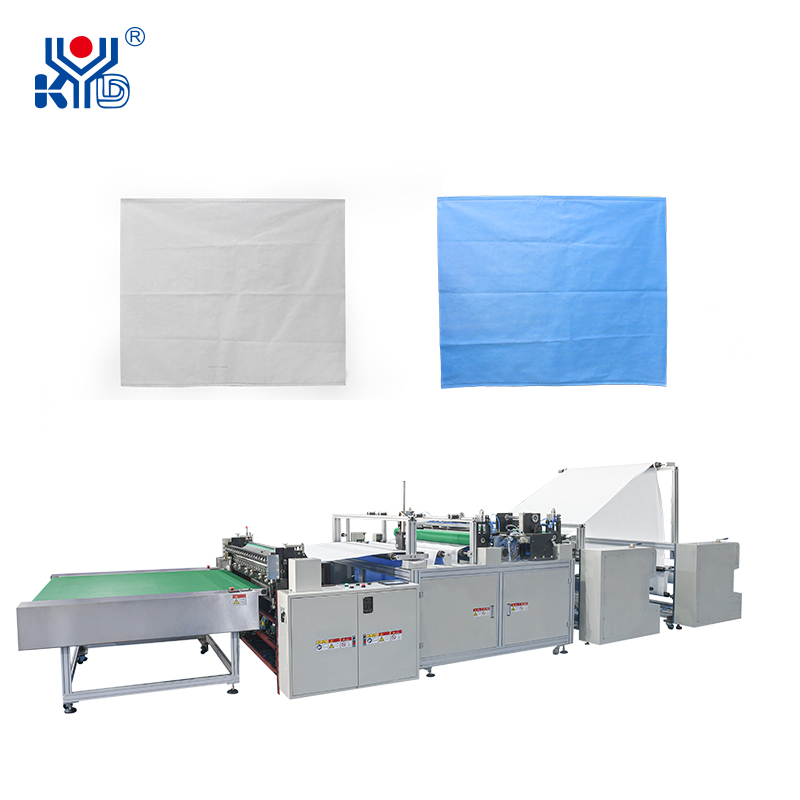

Medical Slip Pad Making Machine

- Date:2023-11-07

- Visits:1087

- Product introduction

- Related products

Product Name

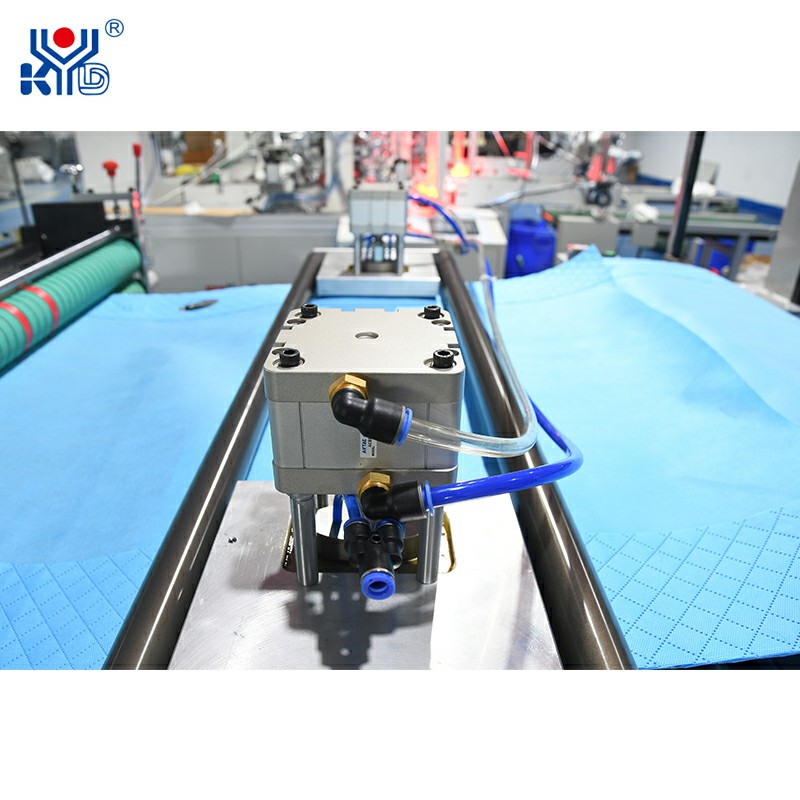

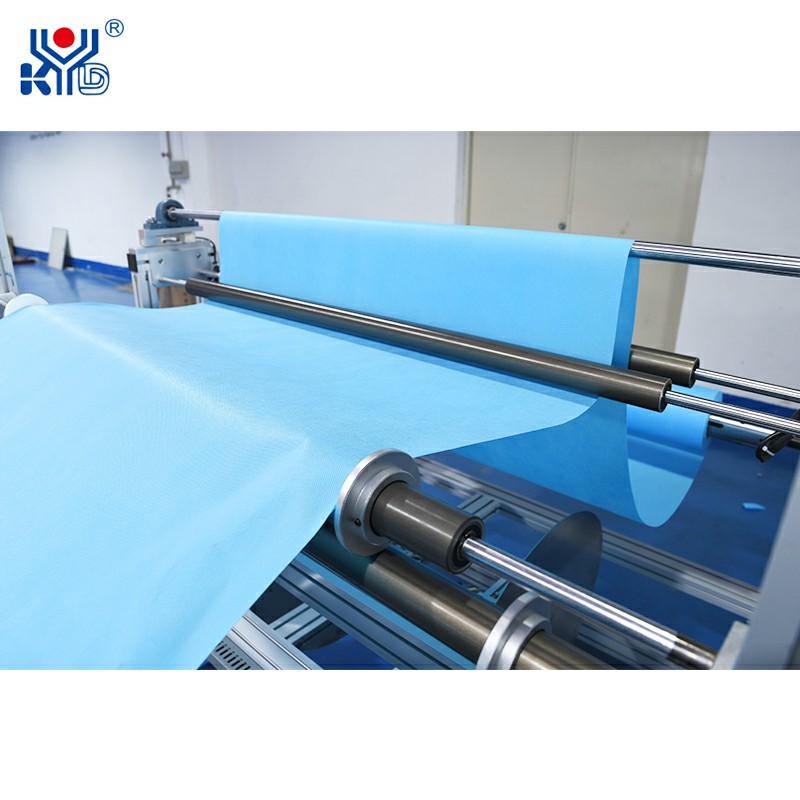

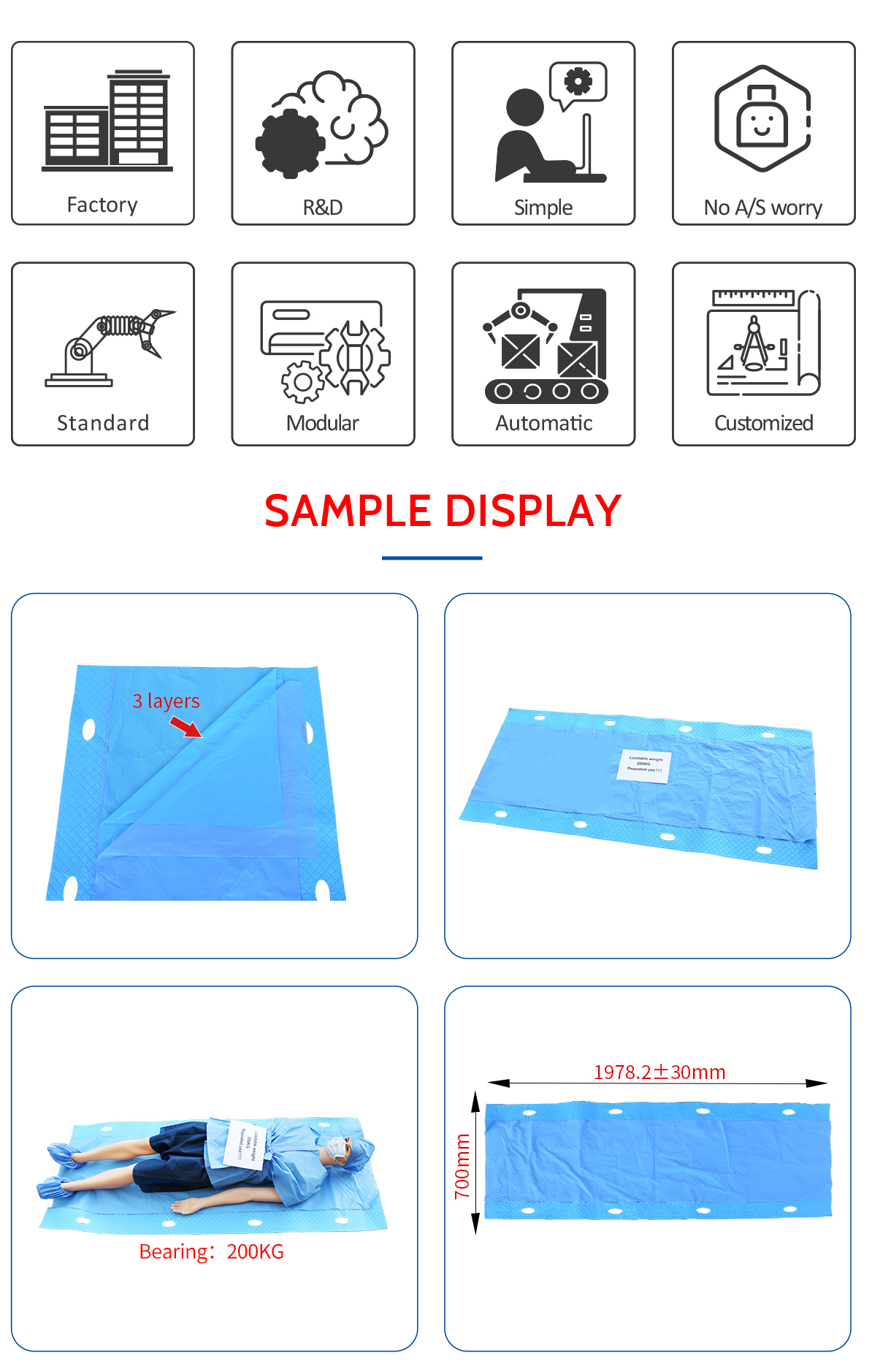

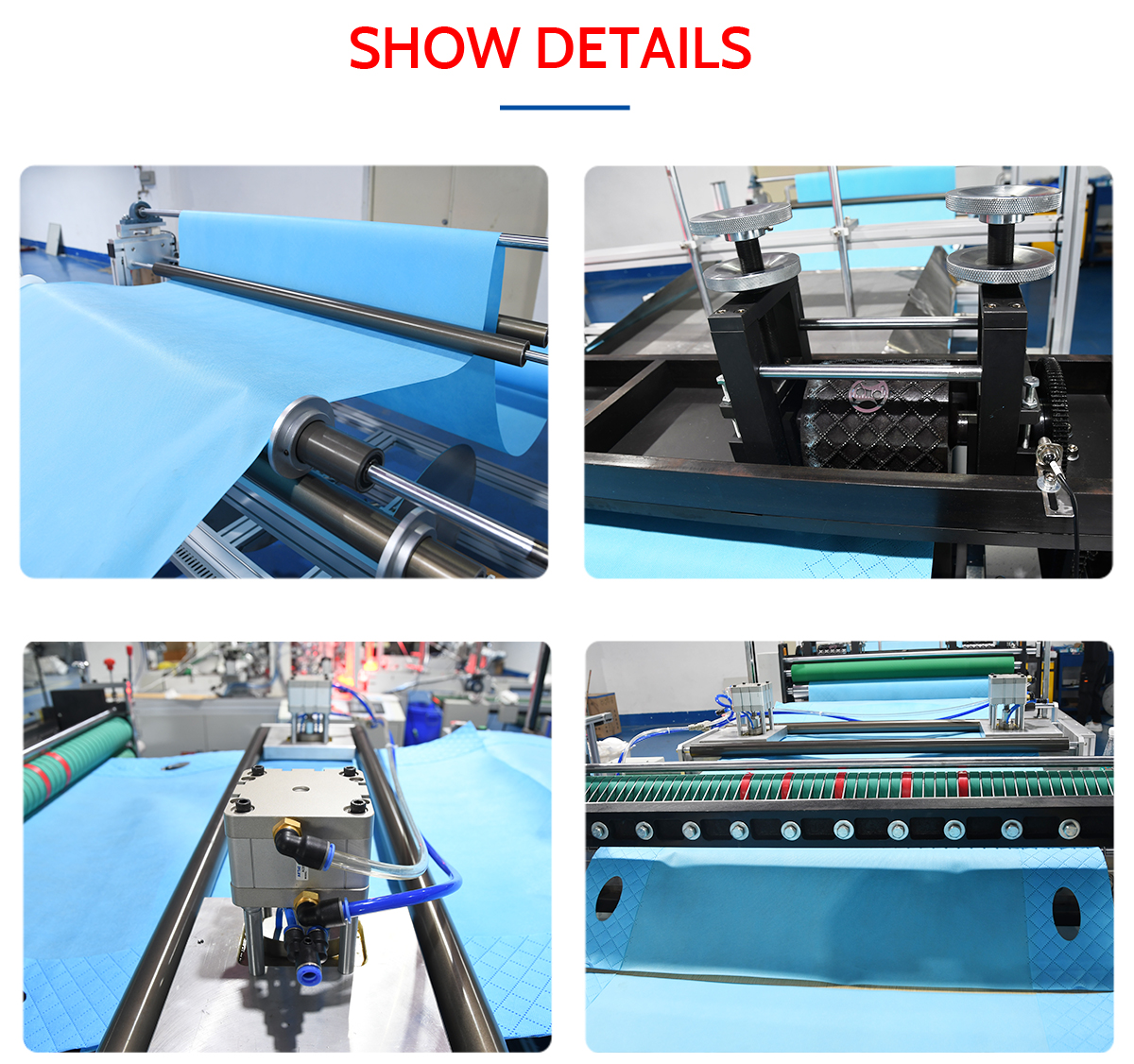

Medical Slip Pad Making Machine

Detection mode

Photoelectric detection

Size

5500*1500*1700mm

Voltage

220V

Power

5KW

Pressure

6kg/cm2

Yield

5-7pcs/min

Control Mode

PLC

The power supply of the machine is AC AC220V, the total power is 5.5KW, the maximum working current is 36A, the diameter of the power socket line shall not be less than 3.4 square copper core line, the machine must be reliably grounded, the machine should be first ventilated and then energized, the working environment temperature of all sensors should be above 0 degrees, and the air pressure should be maintained at 6-8kg.

Safety check: check to make sure there is no debris on the worktable and no other person is operating the machine. After safety inspection and normal power supply, the machine should perform the following operations.

5. 1. The start

Click: press the click button, the machine will run at the original speed during pressing, when release the button, the machine will stop immediately.

Linkage: click the start button, the machine will continue to move at the set speed until the stop (red) or emergency stop (mushroom head) button is pressed.

5. 2. Stop

1. Normal shutdown

Press the stop (red) button and the machine will stop running.

2. Emergency shutdown

When the machine stops or operates abnormally, the machine stops immediately. After restarting, the cylinder, motor and switch can be operated again after the origin is restored. If the origin cannot be restored again, the elimination method is to turn OFF the power supply and remove the pressure source gas. After manual adjustment, connect the air pressure source and send power again to start the normal operation.

-

Medical Slip Pad Making Machine

Automatic PE Apron Making Machine

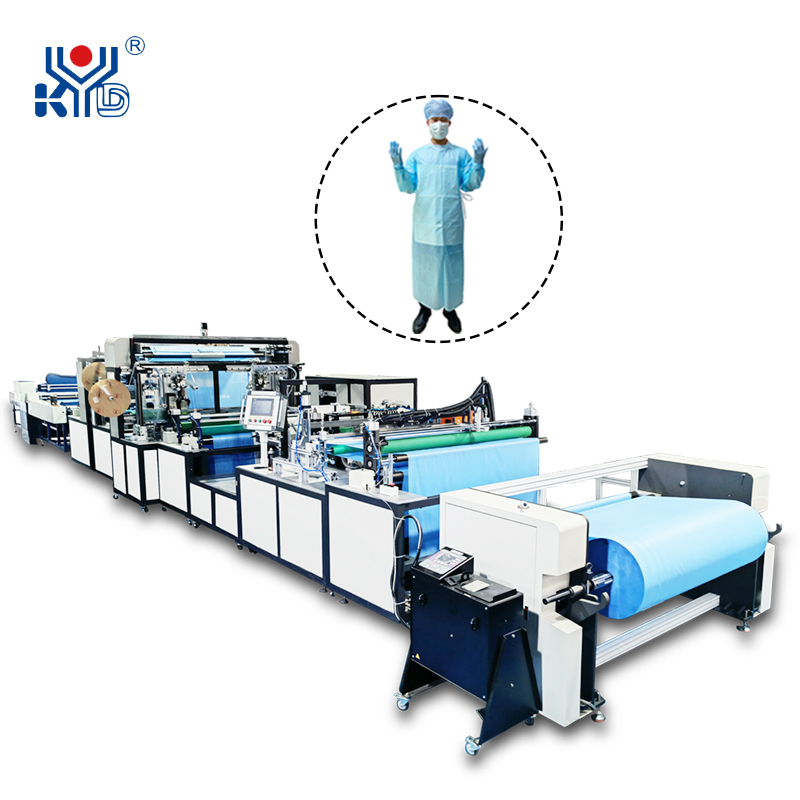

Automatic Disposable Surgical Gowns Body Making Machine

Automatic Non-woven Scrub Gowns Making Machine

Disposable Medical Examination Pants Making Machine

Automatic Surgical Pack Making Machine

Automatic Disposable Protective Gowns Body Making Machine

English

English